Description

Features of automatic steel packing machine for sale

1. Lift cover type panel, easy maintenance.

2. New electric heating device, fast heating, long service life.

3. Single chip electronic control, complete functions, easy operation.

4. Four bundling methods to ensure a wide range of customer bundling requirements.

5. Low cost of packing string.

Automatic steel packing machine performance index:

1. Bundling diameter range:Φ100~Φ400

2. Bundle bale weight:1500KG-4000KG

3. Bundle bale shape:round

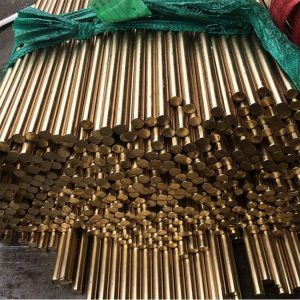

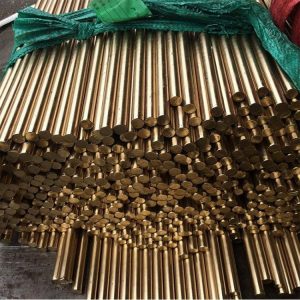

4. Suitable steel specification:deformed steel bar, (Φ10~140)round bar

5. Bundling object temperature:≤300℃

6. Bundling wire material and specification:Q195,specification is Φ5.5~7(recommend Φ6.5)green rod

7. Bundling type:single wrap, single knot

8. Knot angle:630°

9. Single track bundling time:7~12 seconds

10. Working temperature:-10℃-40℃

11. Control mode:manual and automatic with the function of interlocking communication with the production line

12. Installation weight:~4tons

13. Power supply:three-phase four-wire AC380V+PE 50HZ

14. Installed gross capacity:16KW

15. Contour size of the unit:3600x1250x2050

Advantages of automatic steel packing machine supply

1. Increased Efficiency:

The automatic steel packing machine streamlines the packaging process, reducing manual labor and increasing productivity. It can handle large volumes of steel products with precision and speed.

2. Improved Safety:

With automated features, the machine minimizes the risk of accidents and injuries associated with manual handling. It ensures a safe working environment for operators and reduces the chances of product damage.

3. Consistent Packaging:

The machine ensures consistent and uniform packaging, eliminating variations caused by human error. This leads to improved product quality and customer satisfaction.

4. Cost Savings:

By automating the packaging process, the machine reduces labor costs and increases overall operational efficiency. It optimizes material usage, minimizing waste and saving on packaging materials.

5. Versatility:

The automatic steel packing machine is adaptable to different sizes and shapes of steel products. It can handle various packaging requirements, providing flexibility for different industries.

6. Real-time Monitoring:

The machine is equipped with advanced sensors and monitoring systems that allow operators to track the packaging process in real-time. This enables timely adjustments and ensures optimal performance.

7. Durability:

Built with high-quality materials, the machine is designed to withstand the demanding nature of steel packaging. It offers long-term reliability and requires minimal maintenance.

8. Eco-friendly:

The machine promotes sustainability by reducing packaging waste and optimizing material usage. It contributes to a greener environment by minimizing the carbon footprint associated with packaging processes.

Automatic profile steel packing machine maintenance

1. Efficient and Reliable:

The Automatic Profile Steel Packing Machine Maintenance is designed to ensure the smooth operation and longevity of profile steel packing machines.

2. Preventive Maintenance:

Regular maintenance helps identify and address potential issues before they become major problems, reducing downtime and increasing productivity.

3. Lubrication System:

The machine is equipped with an advanced lubrication system that ensures all moving parts are properly lubricated, minimizing friction and wear.

4. Cleaning and Inspection:

The maintenance process includes thorough cleaning of the machine and inspection of key components to detect any signs of damage or wear.

5. Calibration and Adjustment:

The machine is calibrated and adjusted to maintain optimal performance, ensuring accurate and consistent packaging of profile steel.

6. Replacement of Wear Parts:

Worn-out parts are identified and replaced during maintenance to prevent breakdowns and maintain the machine's efficiency.

7. Documentation and Reporting:

Detailed maintenance records are kept, providing a comprehensive history of the machine's maintenance activities for future reference.

8. Cost-effective Solution:

Regular maintenance helps extend the lifespan of the machine, reducing the need for costly repairs or replacements in the long run.

As an automatic profile steel packing machine manufacturer and producer, Yushun is well-known at home and abroad for the high quality steel rolling equipment we produce. We sincerely welcome new and old customers to come to consult our equipment!

Related news of automatic profile steel packing machine

Applications of automatic steel packing machine in industrial

Truly Fully Automatic Steel Packing Machine

Working principle of automatic profile steel packing machine

How to use the automatic steel packing machine for sale safely?

Advantages of automatic steel bar packing machine

Daily maintenance of automatic steel bar packing machine

How to pack and transport automatic profile steel packing machine?

Benefits of customized automatic profile steel packing machine

Proper maintenance of fully automatic steel packaging machines

Reviews

There are no reviews yet.