Description

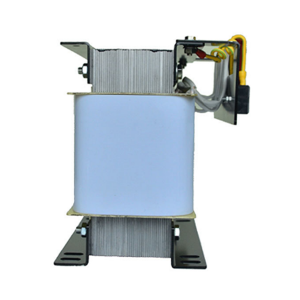

Galvanizing Wire Annealing Furnace type:

• The whole furnace adopts countercurrent open fire heating type, each section controls temperature and adjusts atmosphere separately. Using gas heating technology, the main characteristics of the furnace type are: open flame heating, oxygen and oxygen combustion and control.

• Total thermal risk control technology can maximize gas energy consumption and reduce production and operating costs compared to other furnace types. Temperature control, wind and gas ratio coefficient, safety failure, etc. are fully controlled by the program.

• The whole furnace is composed of multiple furnace bodies, and the wire inlet is respectively equipped with a heating section, a heating section, a heating section, a heating section and a heating section. Each section of heating is relatively independent and influences each other.

• The front and rear steel wire inlet and outlet of the furnace are equipped with electric switch furnace doors, easy to operate.

• Smoke exhaust system: the smoke is discharged from the inlet wire, through the air heat exchanger, furnace pressure electric regulating valve, through the smoke pipe into the steel chimney natural emission.

2) Furnace lining structure

The furnace body adopts mullite refractory brick to strengthen the heat preservation of the furnace and improve the thermal stability during production.

External walls are made of kom-mullite poly brick + thermal insulation board

3) Gas supply main and combustion safety system

The gas supply main pipe is composed of electric regulating valve and solenoid valve.

4) Automatic control system and instrument detection device

• The gas pressure regulator is set in front of the furnace to ensure the stable operation of the control system.

• All hot air combustion system and a factor (air fuel ratio) real-time control.

5) Electrical configuration:

Heat treatment computer control system includes Germany Siemens S7 series PLC and Taiwan Advantech brand industrial computer IPC.

the lower computer is Germany Siemens S7 series PLC.

| No. | Item | Specification |

| 1 | Type of fuel | Natural gas |

| 2 | Electrical Power | Three-phase five-wire system |

| 3 | Length furnace | 27.5m |

| 4 | Net width inside furnace | 1.39m |

| 5 | Number of heating sections | 4 |

| 6 | Heating power | 95 ×104×4.18KJ/h |

| 7 | Max Temperature | 950℃ |

| 8 | Heating Method | Side Heating |

| 9 | Number of burners | 28 |

| 10 | Approve lines | 40 |

| 11 | Furnace temperature control accuracy | ±3℃ |

| 12 | Waste heat recovery and | High efficiency plug-in |

| heat exchange device type | tubular heat exchanger |

Show Annealing Furnace :Annealing steel wire for 30lines/48lines/50lines/60lines

for galvanizing wire ,for Hot dip galvanizing wire,electric galvanizing wire.

Each furnace temperature: automatic + manual control

(Automatic control mode when the computer automatically adjusts the gas and air flow: manual control when the gas flow and air flow are manually adjusted.

• Automatic adjustment of gas and air ratio: automatic control of air excess coefficient

Our Annealing Furnace: Insulation thickness and control system

You will see our The difference between the set temperature and the actual temperature is 1.2-1.5 ℃; Within 2 ℃;

This is an excellent device; The tolerance I provided is ± 3 ℃

Waste heat recovery and heat exchange device type

High efficiency plug-in tubular heat exchanger

Reviews

There are no reviews yet.