Description

https://www.josencnc.com/VMC-855-CNC-Vertical-Machining-Center.html

The machine is suitable for communication, medical machinery, auto and locomotive parts, etc. The motor and screw are designed with direct drive, which can greatly save non-machining time. The spindle adopts short nose design, which has better strong rigidity. The standard 24 disc type tool changer implements automatic tool change, which saves the time of tool change process.

1.This model is suitable for communication, medical equipment, automobile and

locomotive parts, 3C products processing.

2.Three axis motor and screw adopt direct drive design, no belt or gear drive

caused by noise, clearance and vibration problems, three axis rapid displacement

up to 48m/min, greatly saving non-machining time.

3.The three axes guide rail and screw adopt fully enclosed shield, which has

very good protection performance.

4.The three axes adopt C3 grade Φ40*P16mm screw, and adopt the assembly

process of pre-stretching at both ends to strengthen the axial rigidity and

reduce the thermal extension of the screw.

5.The standard 24 disc type tool changer implements automatic tool change,

saving the time of tool change process.

6.Fully enclosed shield to protect the cleanliness of machine tools and

working environment, improve operational safety, with transparent protection

windows, more convenient to work.

7.Fully enclosed electric cabinet, active airflow circulation design,

professional cooling system of the cabinet makes the cabinet more dustproof and

ventilated, and can control the temperature of the cabinet, prolong the service

life of the device to reduce the failure rate, reduce downtime and maintenance

costs.

8. Large capacity, large flow processing cooling system, automatic plus

manual control, can fully meet the requirements of strong cutting, reduce tool

damage and improve product quality, reduce the cost of use.

| ITEM | UNIT | DV-855+ |

| Travel | ||

| X-axis travel | mm | 800 |

| Y-axis travel | mm | 500 |

| Z-axis travel | mm | 550 |

| Worktable size | ||

| Working table size (X*Y) | mm | 1000×500 |

| Max.loading capacity of working table | kg | 600 |

| Table T-slot size (width * number of slots * spacing) | number | 18x5x80 |

| Spindle | ||

| Spindle speed | rpm | 12000 |

| Spindle drive form | Direct driven | |

| Spindle power | kW | 7.5/11 |

| Spindle bore specification | BT40 | |

| Distance from spindle to table surface |

mm | 120-670 |

| Spindle feed | ||

| Rapid feed rate(X,Y,Z) | m/min | 48/48/48 |

| Cutting feed rate | mm/min | 10000 |

| Tool magazine(Optional) | ||

| Tool magazine capacity | arm type 24 | |

| Tool diameter/adjacent tool space | mm | Φ80/Φ150 |

| Max. Tool length | mm | 300 |

| Max. Tool weight | kg | 8 |

| Accuracy | ||

| Positioning accuracy | mm | ±0.005 |

| Reproduction accuracy | mm | ±0.003 |

| Others | ||

| Controller | kg/cm² | 0i-MF/M80 |

| Air pressure demand | kg/cm2 | 6 |

| Power demand | kVA | 25 |

| Machine weight | T | 5 |

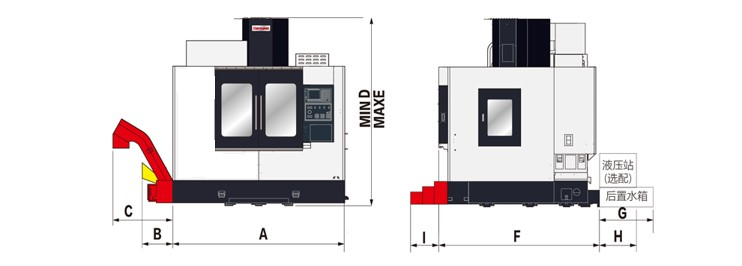

| Model | A | B | C | D | E | F | G | H |

| DV-855+ | 2500 | 395 | 1050 | 2520 | 2800 | 2455 | 345 | 550 |

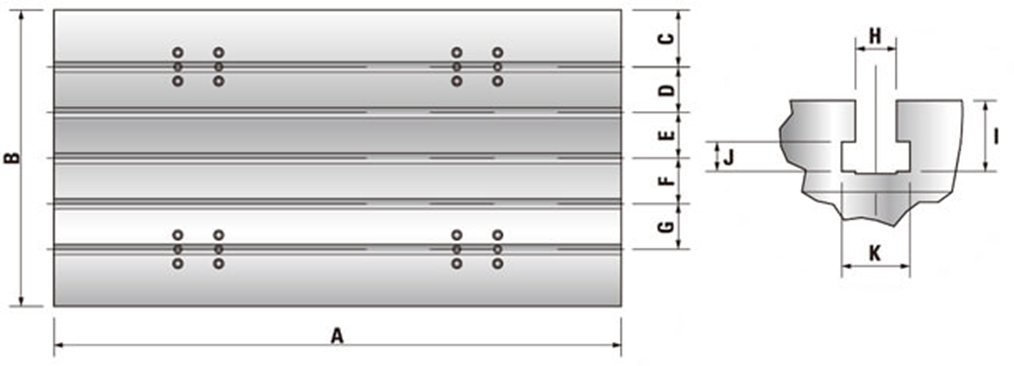

| Model | A | B | C | D | E | F | G | H | I | J | K | T-slot number |

| DV-855+ | 1000 | 500 | 90 | 80 | 80 | 80 | 80 | 18 | 31 | 13 | 30 | 5 |

Reviews

There are no reviews yet.